Valves and Seats remain the #1 reason customers must service their fluid ends. Increasing the number of stages pumped per day by cutting down maintenance intervals is more important than ever.

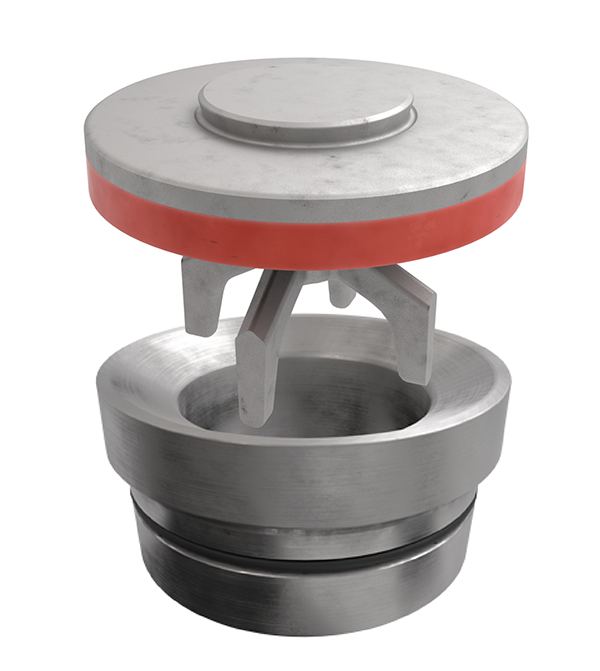

GD Redline valves and seats are industry leaders, designed for maximum performance and reliability, with the full-open, bonded design providing optimal flow efficiency and maximum sealing.

In line with GD’s commitment to continuous innovation, the V3 valve has undergone a complete redesign to improve metallurgy and heat treatment resulting in enhanced wear resistance and strength.

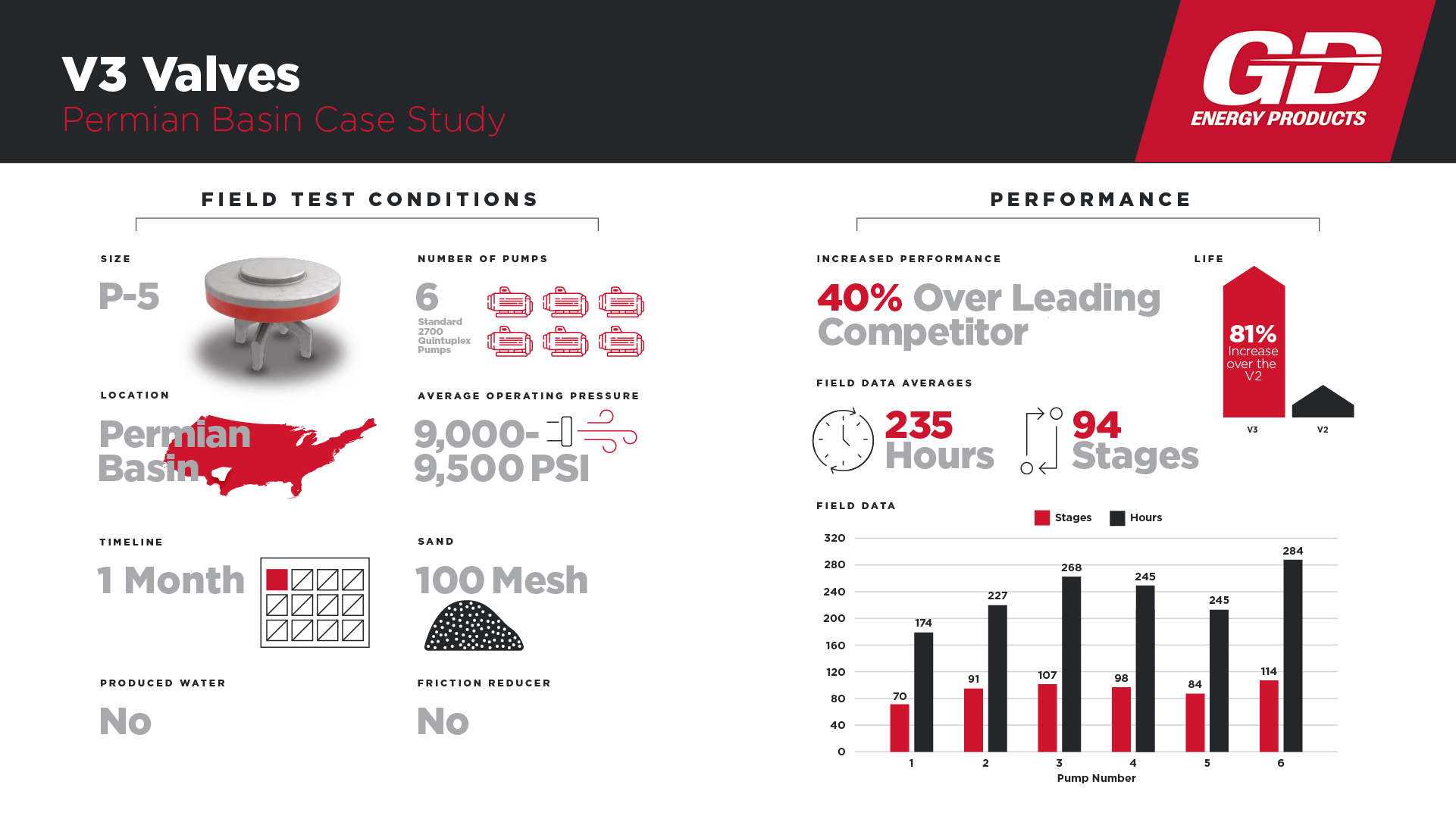

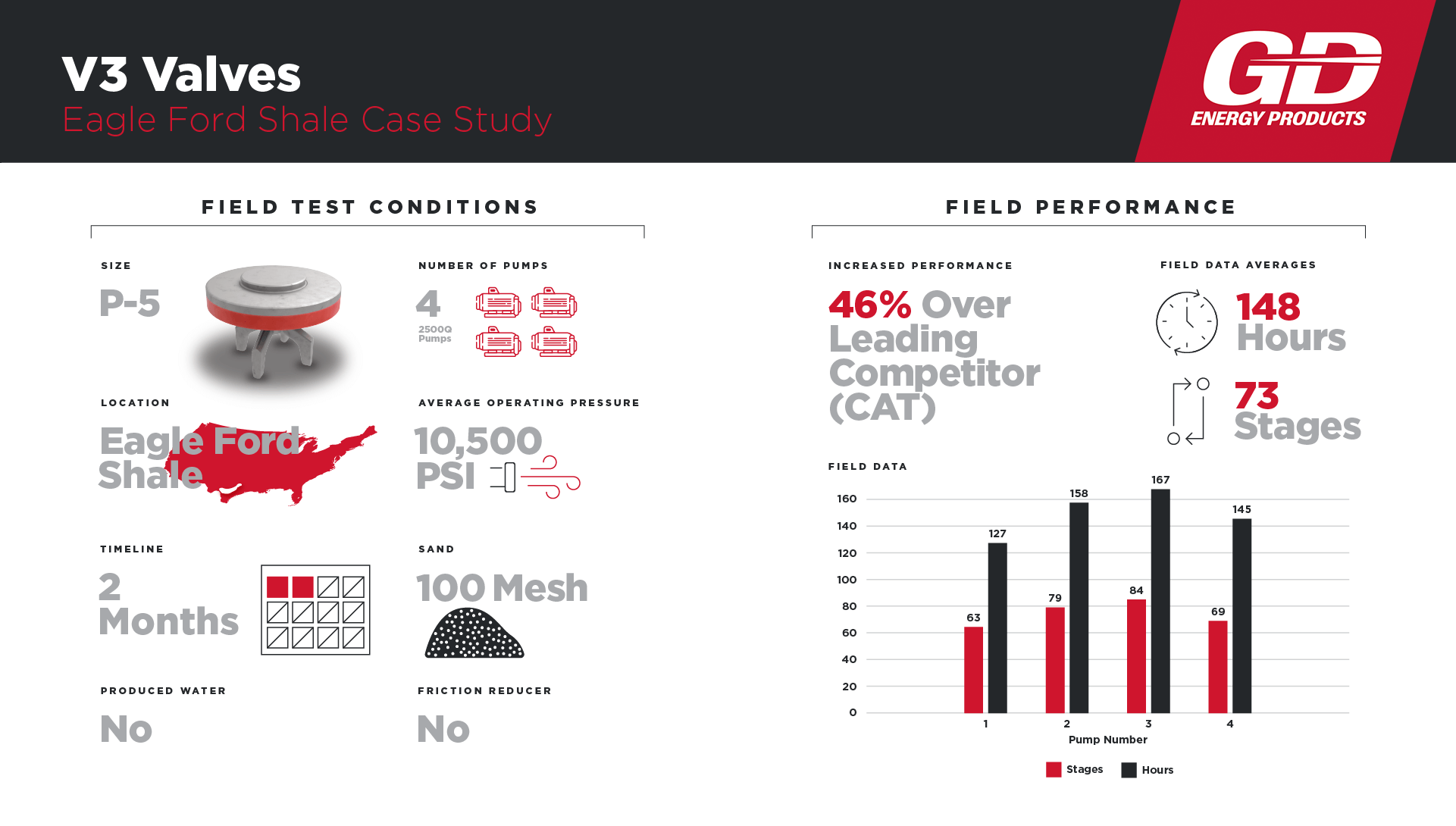

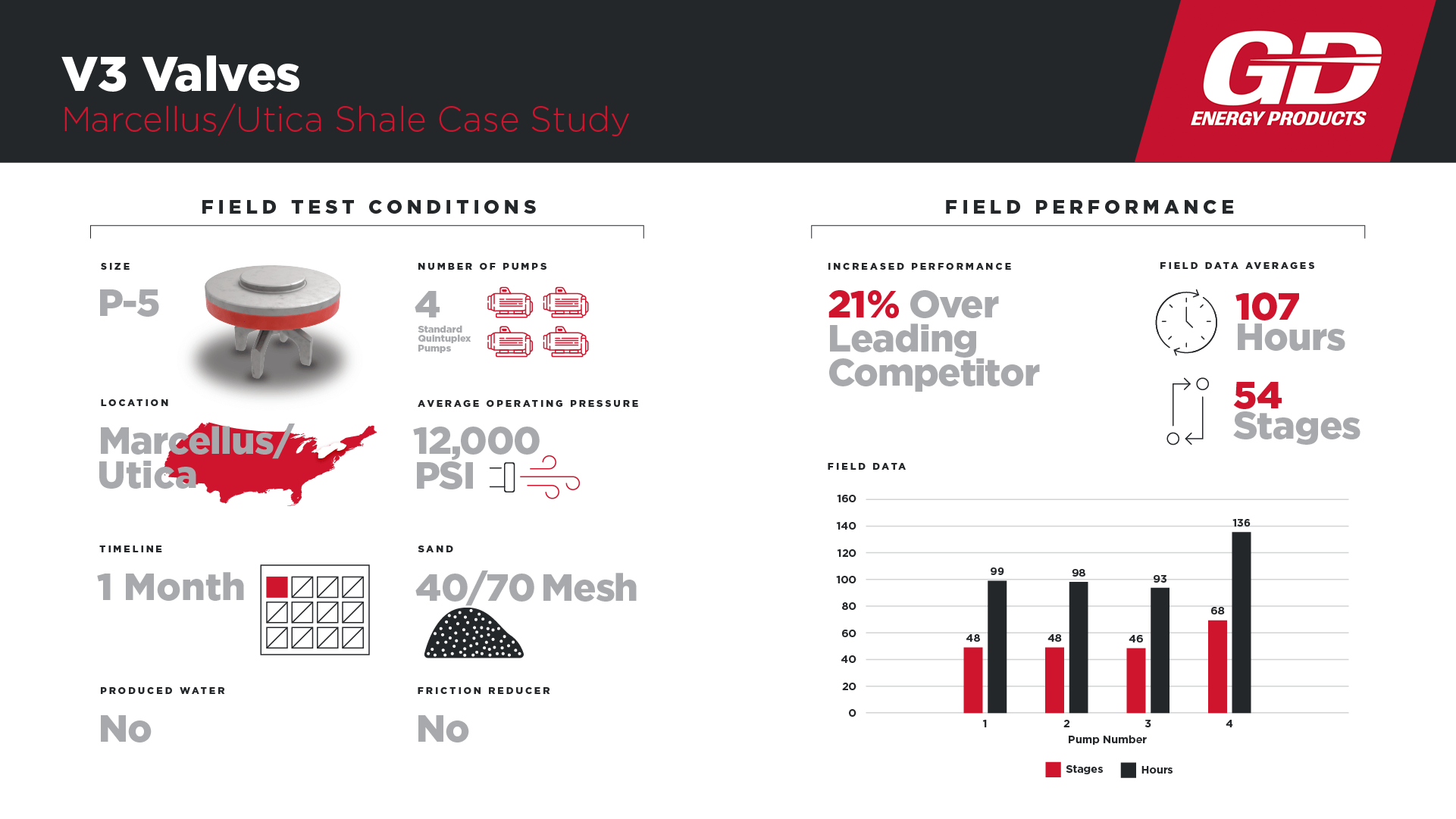

During field trials in the Eagle Ford, Permian and Marcellus shale plays, increased performance of up to 46% over the leading competitor was observed. In the Permian Basin, performance of the V2 and V3 could be compared, with an increase in performance of 81% witnessed.

Available for any make or model of pump, GD Energy Product's V3 valve is suitable for use with any standard fluid end utilizing P-4 and P-5 valve configuration. Backed by our 24/7 service and support, and part of our industry leading Parts on Demand program, Redline consumables are the ideal way to maximize service life and get the most out of your equipment.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.